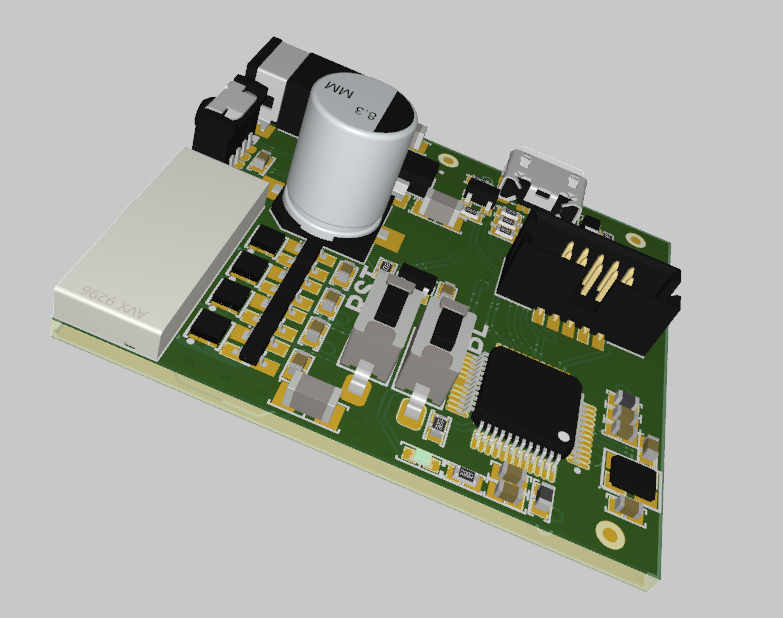

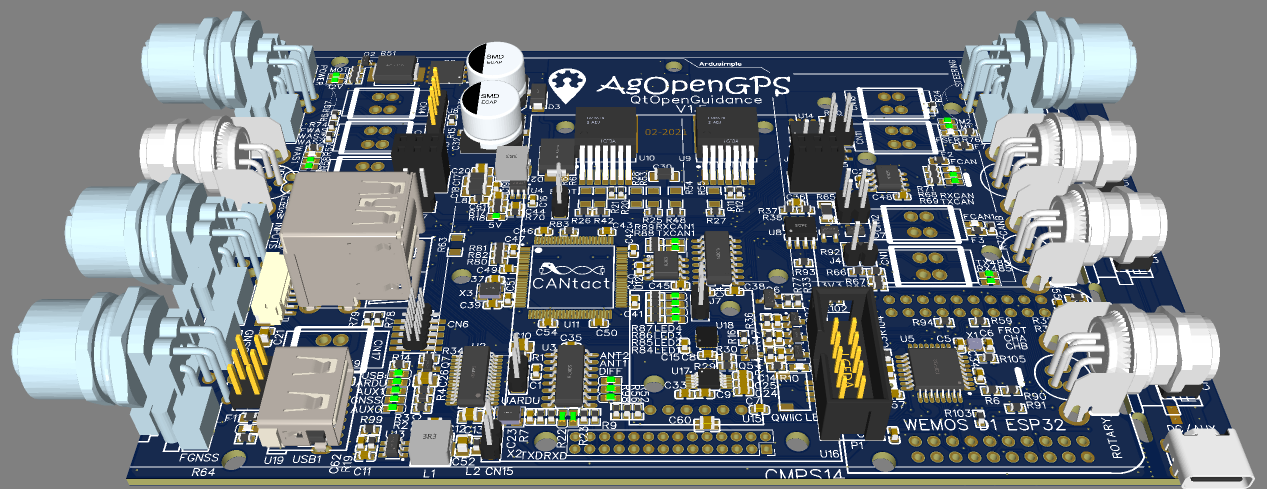

Components were mechanically redesigned to have small metal tabs or end caps that could be directly soldered to the surface of the PCB. The design approach first demonstrated by IBM in 1960 in a small-scale computer was later applied in the Launch Vehicle Digital Computer used in the Instrument Unit that guided all Saturn IB and Saturn V vehicles. Much of the pioneering work in this technology was done by IBM. By the late 1990s, the great majority of high-tech electronic printed circuit assemblies were dominated by surface mount devices. By 1986 surface mounted components accounted for 10% of the market at most, but was rapidly gaining popularity. Surface-mount technology was developed in the 1960s. Surface mounting was originally called "planar mounting". It may have short pins or leads of various styles, flat contacts, a matrix of solder balls ( BGAs), or terminations on the body of the component. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.Īn SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It also allows for more components to fit on a given area of substrate.

In industry, this approach has largely replaced the through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. An electrical component mounted in this manner is referred to as a surface-mount device ( SMD). Surface-mount technology ( SMT) is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). A MOSFET transistor, placed upon a British postage stamp for size comparison.

0 kommentar(er)

0 kommentar(er)